Materials supplied by Lohmann, with or without adhesive, are used in many applications and in a variety of ways and can be applied manually, by hand, or by machine as part of a semi- or fully automatic production process.

To ensure materials are fit-for-purpose, Lohmann has a range of slitting processes to choose from, ensuring the product you receive will have consistent tension and edge-quality throughout the roll.

|

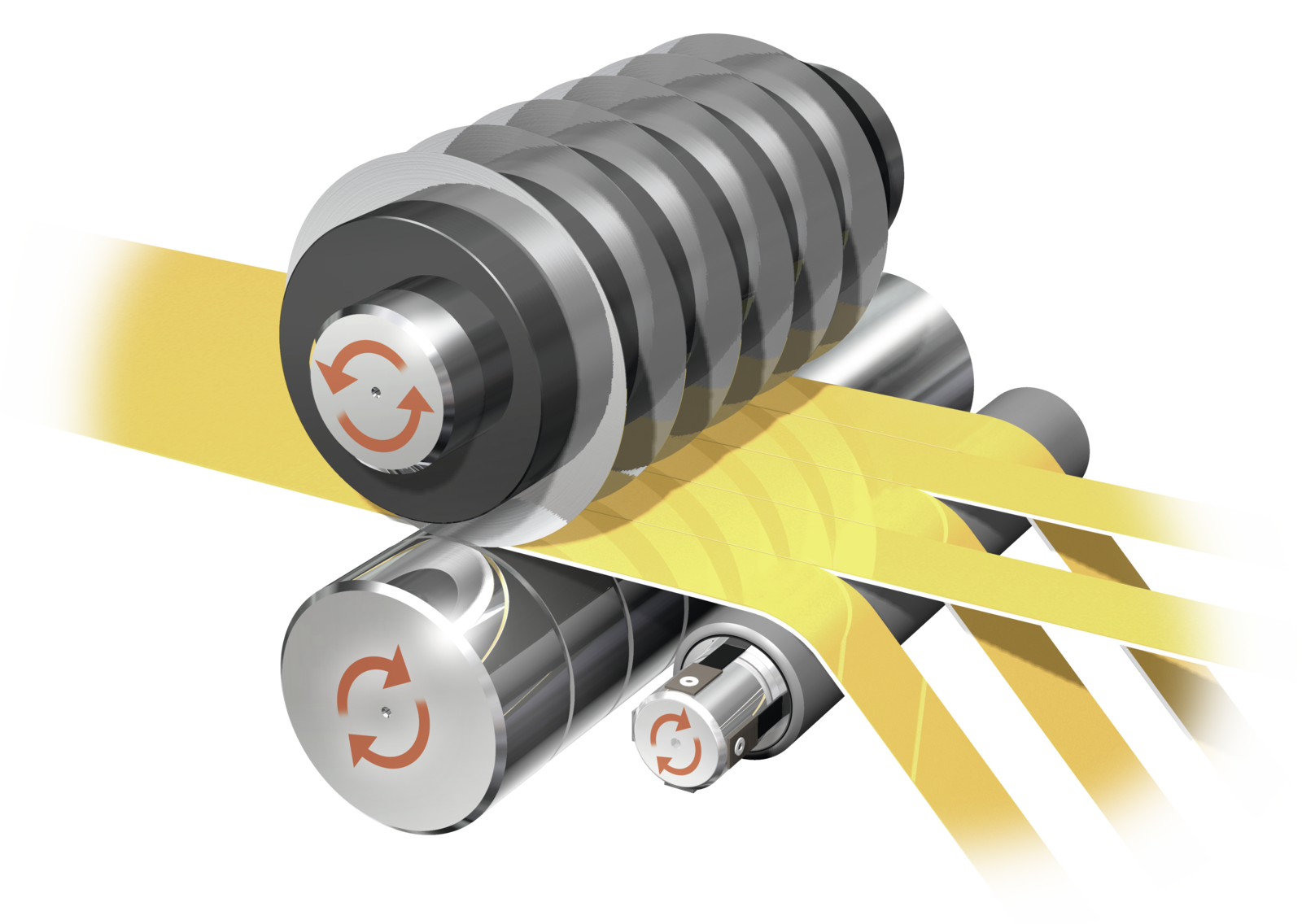

Lathe slitting is the process of spinning material, typically adhesive coated, on a mandrel at high speed while a lubricated circular driven blade cuts (slices) the material to the specified width.

This process can be used for different material types but is typically used to produce narrow slit widths down to 2mm. |

|

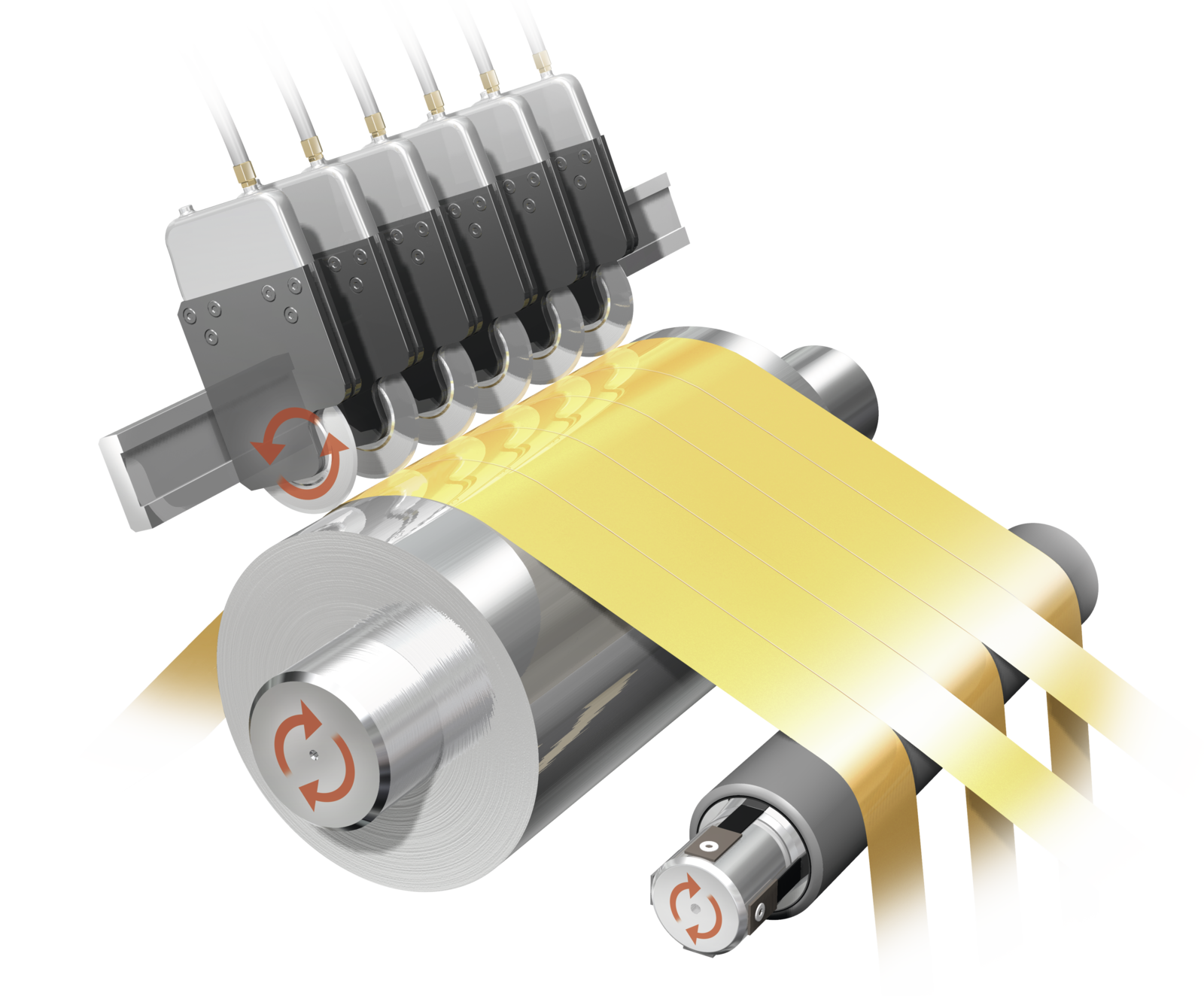

In razor blade slitting the material unwinds from a master roll and is pulled through (multiple) stationary razor blades onto smaller cores. There are two types of razor slitting; razor-in-air and, where the material allows for faster processing speeds, razor-in-groove.

Razor blade slitting produces precise, clean cuts and is best suited for light thin films, foils and non-wovens, paper and open-faced adhesive tapes. Slit rolls width are generally not less than 20mm. |

|

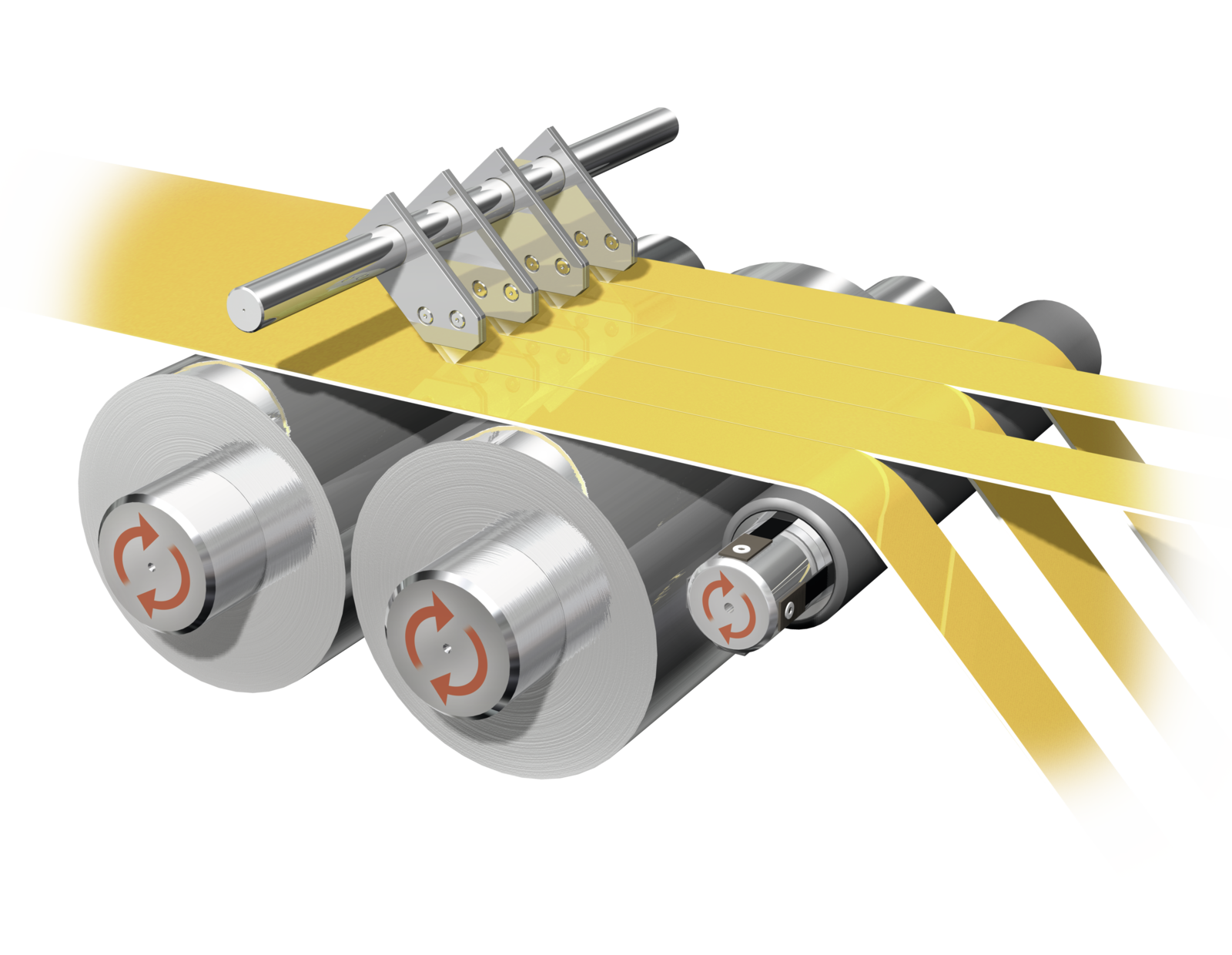

This slitting method uses two rotating knives, a male and female, that work in the same way as a pair of scissors. The female knives are mounted on a shaft, the male knives can either be shaft-mounted or housed in individual holders. The material is cut at the intersection of the two sharp edges. Shear slitting provides high quality clean cuts, with minimum dust generation down to a slit width of 10mm. The process can be applied to a wide variety of thin, medium and thick gauge materials including, but not limited to: films, paper, adhesive tapes and textiles. |

|

Crush cutting involves passing material between circular knives with rounded or dull edges and a hardened steel cylinder/anvil. This resulting action crushes the material, effectively separating the material. This method is ideal for slitting pressure-sensitive adhesive tapes because the crushing process squeezes the adhesive apart, effectively creating a dry, non-sticky edge. However, this method is also ideal for materials of varying rigidity and thickness as well as for textiles, non-wovens, foams and rubbers. This process can product a broad range of slit roll widths, with the minimum being 20mm. |

Please use our enquiry form